Control & Energy Saving

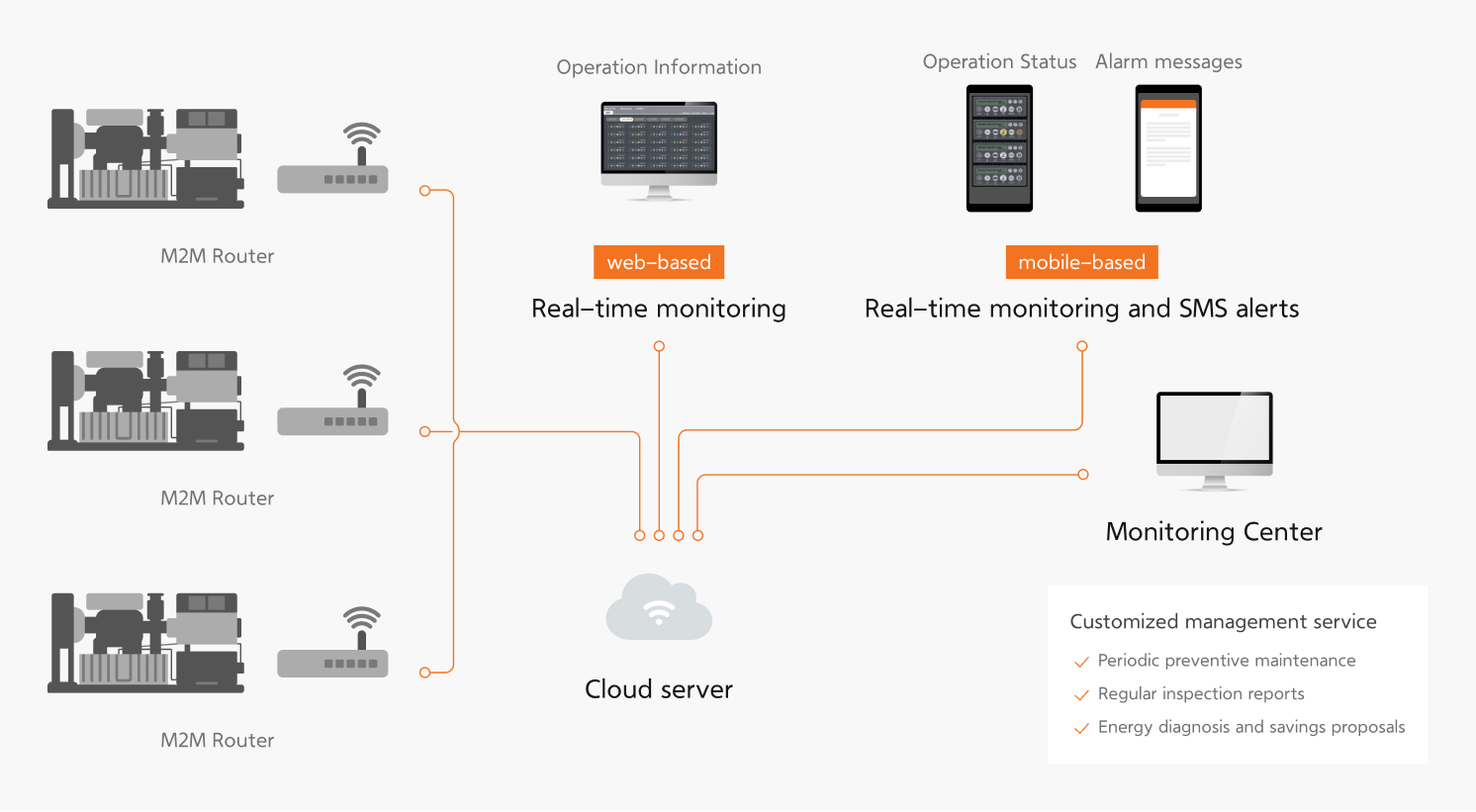

Monitoring System(TIMS- Turbo Integrated Monitoring System)

Real-time monitoring of compressor operation data using IoT and ICT technologies allows for problem prediction and prevention, as well as quick reaction through smartphone alerts when anomalies arise.

Cloud Service Architecture for TIMS

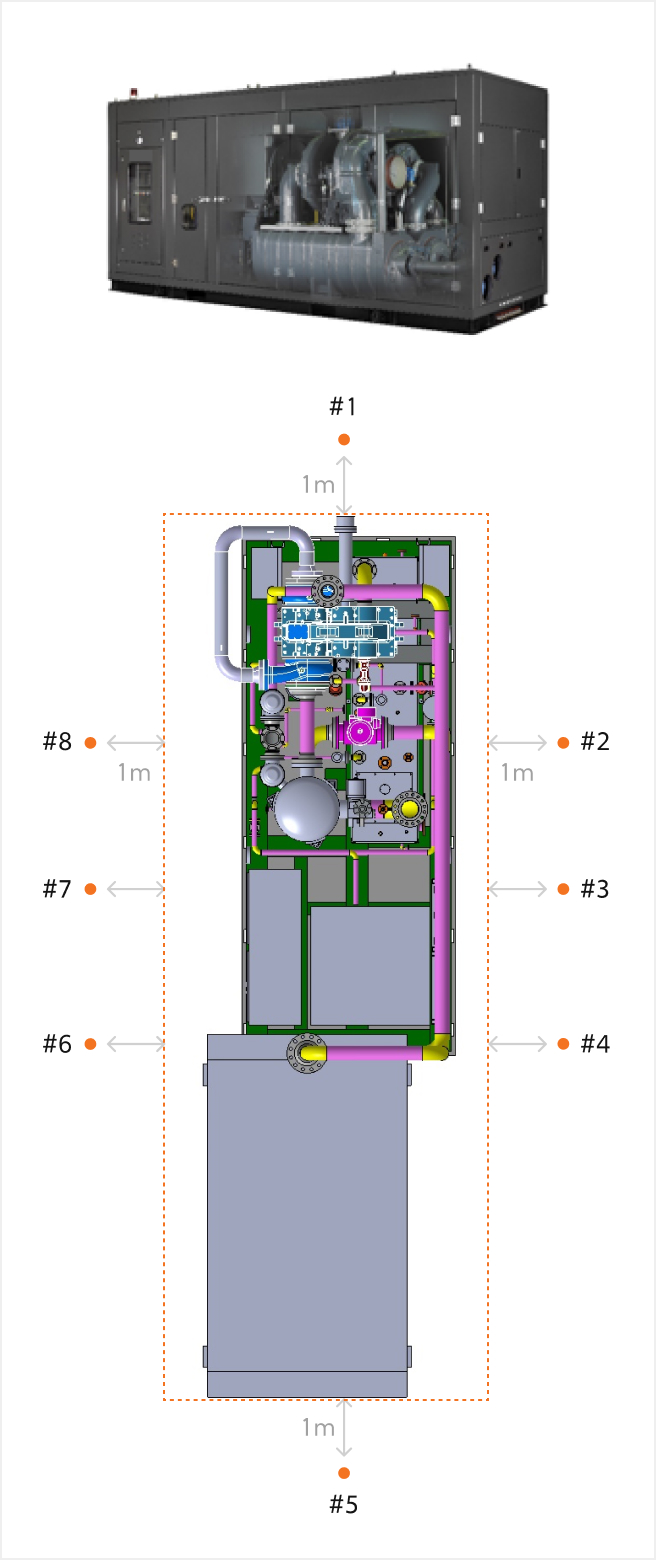

Reducing Compressor Noise to Create a Comfortable Work Environment

To reduce compressor noise, soundproof chambers should be installed, sound-absorbing materials should be fastened to noise sources, and specific silencers should be installed to prevent BOV high-pressure release noise.

-

Work environment improvement

-

Machine life extension

-

Energy efficiency enhancement

-

95 dB(standard specification)

-

85 dB(with noise reduction measures applied)

Operator Training

"With specially designed training programs for compressor operation and maintenance, we promote effective compressor management.

By reducing needless operational disruptions, this enhances worker technical proficiency and boosts productivity."

By reducing needless operational disruptions, this enhances worker technical proficiency and boosts productivity."

Compressor training service provision

Operator trainingRegular

- Target audience

- Regular

- Educational topics

- Basic turbo compressor principles

- Importance of periodic maintenance

- Accident prevention

- Aftermarket products and services introduction

- Main content

- Turbo compressor mechanism theory

- Touch screen practice

- Periodic maintenance program introduction

- Case studies of accidents

- Parts ordering procedure guide

Operator trainingSpecial

- Target audience

- Special

- Educational topics

- Structure & principles

- Preventive maintenance

- Control Logic, etc.

- Main content

- Customer-requested topic training

- Regular Twice yearly(Q2 and Q4) at Korea Changwon Plant

- Irregular Available according to contract terms